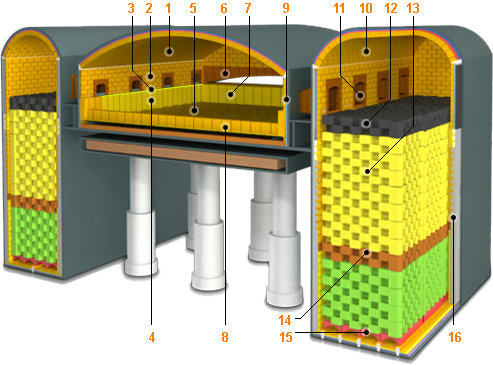

Glassmaking furnace

Magnezit Group offers the whole range of refractory materials for lining of glassmaking furnaces.

Thanks to the wide range of refractories being at the disposal of Magnezit Group it is possible to offer flexible approach to designing of linings maximally taking into account influence of real operational conditions in the glassmaking furnace. Recommendations for application of refractories are developed taking into account requirements to the service life and thermal conditions under which the lining will operate. Complete deliveries provide Customers with all refractory materials used for the lining of a furnace.

The most advanced technologies and equipment are used for production of offered refractory materials as well as high-quality raw materials. All delivered refractory materials are produced at the plants having certified management system according to ISO 9001, ISO 14001, OHSAS 18001.

For carrying out high-quality assembling works and with the aim of ensuring guaranteed service life we can offer the whole range of auxiliary equipment: cutting machines, mixers, gunning machines, systems for compacting of unshaped materials.

Characteristics of refractory materials for this unit

Lining zones:

- Roof of the furnace

- Pool zone

- Glass mass level

- Furnace pool zone

- Bottom

- Loading window

- Rear wall of the pool

- Furnace dam

- Heat insulation of the furnace

- Roof and walls of regenerator

- Burners

- Upper rows of checkerwork

- Regenerator part

- Regenerator checkerwork subdivision

- Support of the regenerator

- Wall of the furnace regenerator

(.mov 3.65 Mb)